- +86 188 5310 8009

- info@northchinametal.com

- Shuntai North Road, High-tech Zone, Jinan City, Shandong Province

Call Us

Mail To

Address

Shuntai North Road, High-tech Zone, Jinan City, Shandong Province

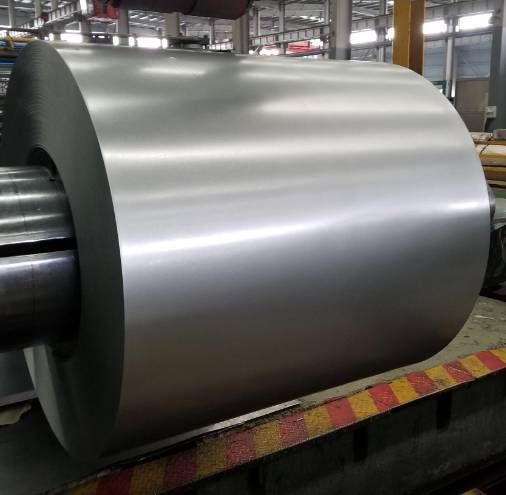

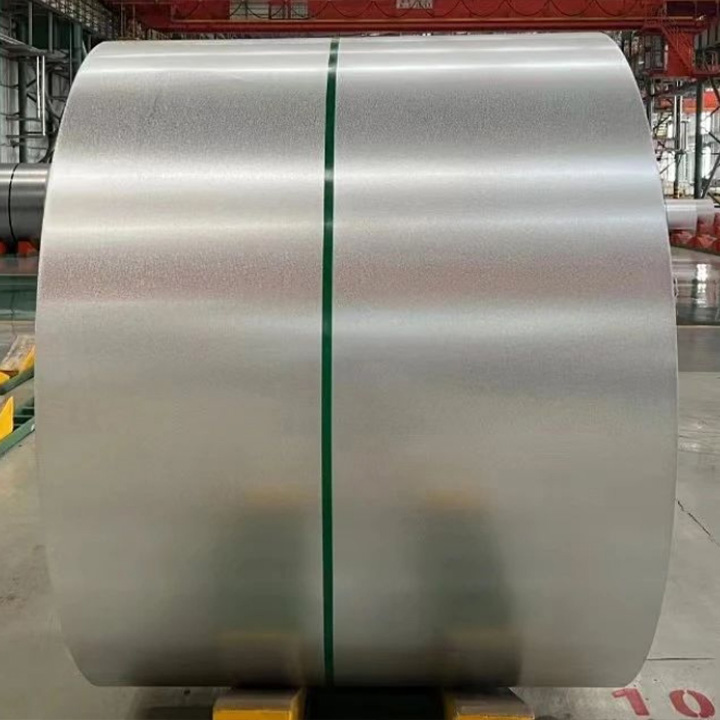

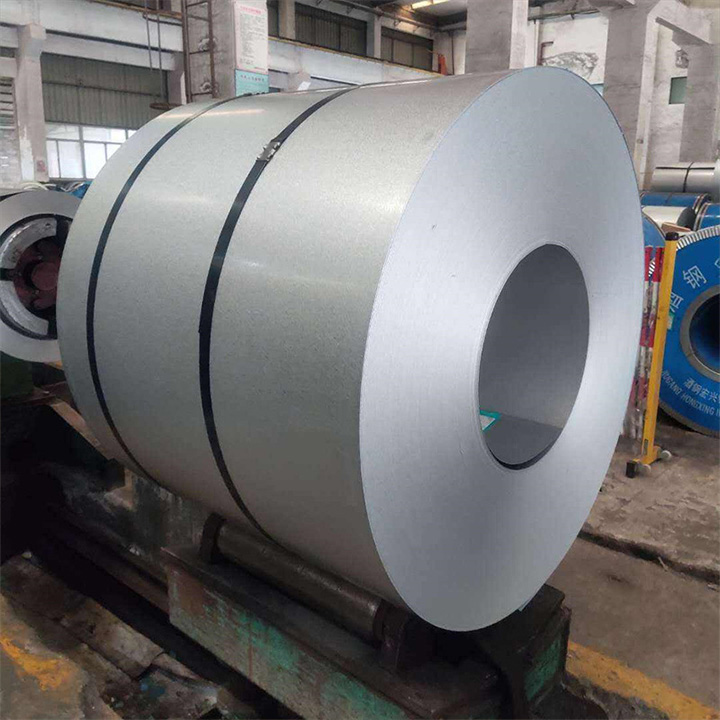

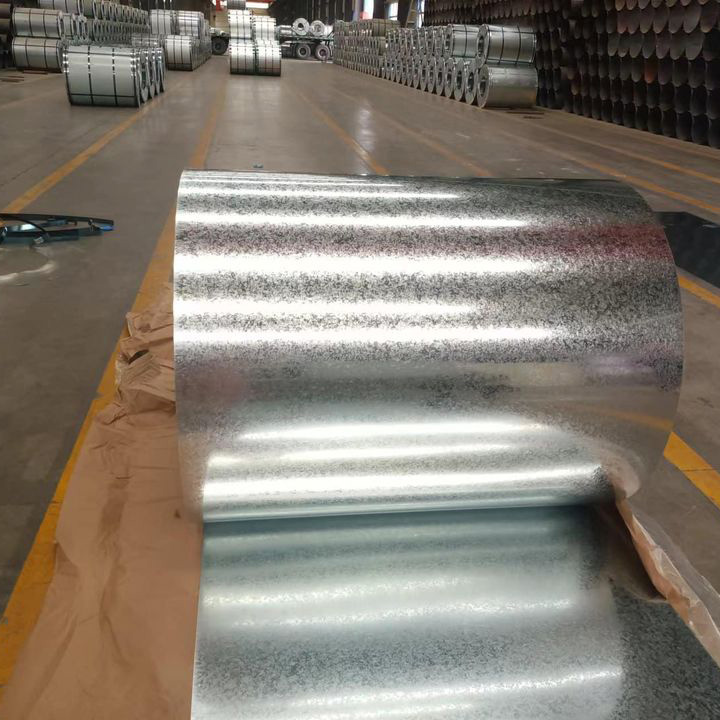

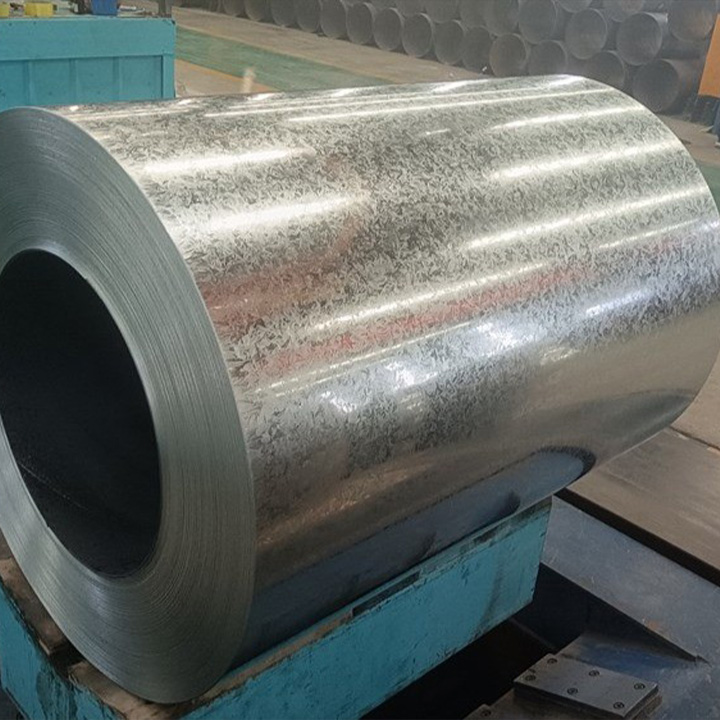

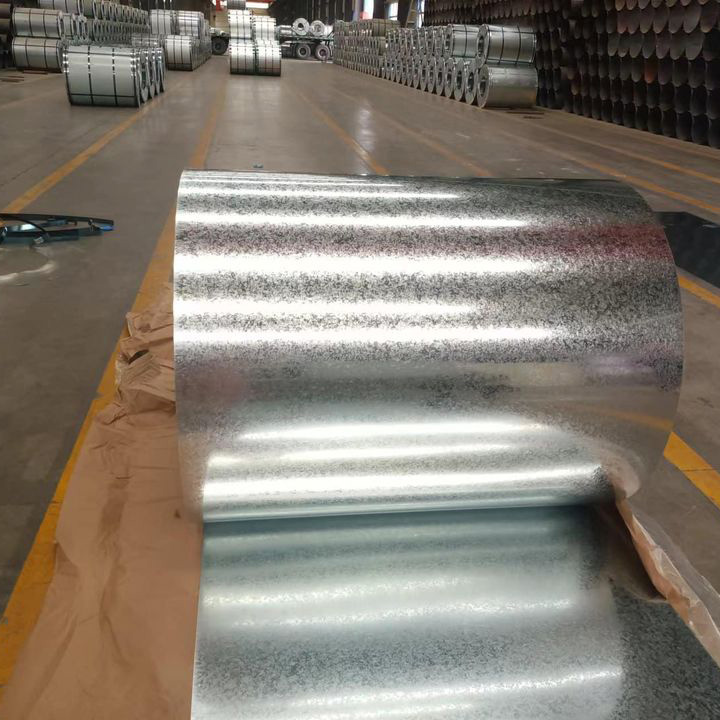

Large pattern galvanized steel coil

Galvanized coils are made by dipping thin steel sheets into a molten zinc bath to adhere a layer of zinc to the surface. They are mainly produced by continuous galvanizing process, that is, the rolled steel sheets are continuously dipped into a molten zinc bath to form galvanized steel coils.

Product Parameters

Product Name | Galvanized Steel Coil |

Package | 3 layers of packing. Inside is craft paper, middle is waterproof plastic film and outside GI steel sheet to be covered by steel |

Grade | spcc DX51D DX52D DX53D DX54D +Z S220GD, S280GD, S350GD |

Zinc coating | Z30-275G/M2 |

Surface Treatment | light Oil,Unoil,dry,chromate passivated,non-chromate passivated |

Thickness | 0.12-4mm |

Spangle | Regular, Minimal, Zero, Big, Small |

Plating definition

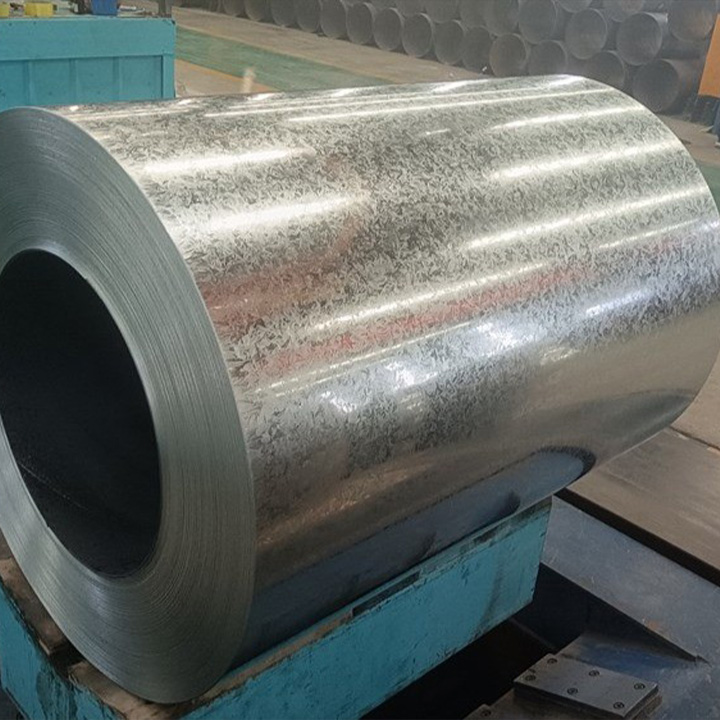

(1) Spangle coating

During the normal solidification process of the zinc layer, the zinc grains grow freely to form a coating with obvious spangle morphology.

(2) Minimized spangle coating

During the solidification process of the zinc layer, the zinc grains are artificially restricted to form a spangle coating as small as possible.

(3) Spangle-free coating

A coating obtained by adjusting the chemical composition of the plating solution, which has no visible spangle morphology and a uniform surface.

(4) Zinc-iron alloy coating

The steel strip after passing through the galvanizing tank is heat treated to form an alloy layer of zinc and iron. This coating has a dark gray appearance and no metallic luster. It is easy to powderize during the intense forming process. It is suitable for coatings that can be directly painted without further treatment except general cleaning.

During the normal solidification process of the zinc layer, the zinc grains grow freely to form a coating with obvious spangle morphology.

(2) Minimized spangle coating

During the solidification process of the zinc layer, the zinc grains are artificially restricted to form a spangle coating as small as possible.

(3) Spangle-free coating

A coating obtained by adjusting the chemical composition of the plating solution, which has no visible spangle morphology and a uniform surface.

(4) Zinc-iron alloy coating

The steel strip after passing through the galvanizing tank is heat treated to form an alloy layer of zinc and iron. This coating has a dark gray appearance and no metallic luster. It is easy to powderize during the intense forming process. It is suitable for coatings that can be directly painted without further treatment except general cleaning.

Defect

The main reasons are: shedding, scratches, passivation spots, zinc particles, thick edges, air knife streaks, air knife scratches, exposed steel, inclusions, mechanical damage, poor steel base performance, wave edges, buckling, size mismatch, stamping, zinc layer thickness mismatch, roller marks, etc.

The main reasons for zinc layer shedding are: surface oxidation, silicon compounds, dirty cold rolling emulsion, too high dew point of oxidation atmosphere and protective gas in NOF section, unreasonable air-fuel ratio, low hydrogen flow, oxygen infiltration in the furnace, low temperature of strip entering the pot, low furnace pressure in RWP section and furnace door suction, low furnace temperature in NOF section, incomplete evaporation of grease, low aluminum content in zinc pot, too fast unit speed, insufficient reduction, too short residence time in zinc liquid, and thick coating.

Description

Product Parameters

Product Name | Galvanized Steel Coil |

Package | 3 layers of packing. Inside is craft paper, middle is waterproof plastic film and outside GI steel sheet to be covered by steel |

Grade | spcc DX51D DX52D DX53D DX54D +Z S220GD, S280GD, S350GD |

Zinc coating | Z30-275G/M2 |

Surface Treatment | light Oil,Unoil,dry,chromate passivated,non-chromate passivated |

Thickness | 0.12-4mm |

Spangle | Regular, Minimal, Zero, Big, Small |

Plating definition

(1) Spangle coating

During the normal solidification process of the zinc layer, the zinc grains grow freely to form a coating with obvious spangle morphology.

(2) Minimized spangle coating

During the solidification process of the zinc layer, the zinc grains are artificially restricted to form a spangle coating as small as possible.

(3) Spangle-free coating

A coating obtained by adjusting the chemical composition of the plating solution, which has no visible spangle morphology and a uniform surface.

(4) Zinc-iron alloy coating

The steel strip after passing through the galvanizing tank is heat treated to form an alloy layer of zinc and iron. This coating has a dark gray appearance and no metallic luster. It is easy to powderize during the intense forming process. It is suitable for coatings that can be directly painted without further treatment except general cleaning.

During the normal solidification process of the zinc layer, the zinc grains grow freely to form a coating with obvious spangle morphology.

(2) Minimized spangle coating

During the solidification process of the zinc layer, the zinc grains are artificially restricted to form a spangle coating as small as possible.

(3) Spangle-free coating

A coating obtained by adjusting the chemical composition of the plating solution, which has no visible spangle morphology and a uniform surface.

(4) Zinc-iron alloy coating

The steel strip after passing through the galvanizing tank is heat treated to form an alloy layer of zinc and iron. This coating has a dark gray appearance and no metallic luster. It is easy to powderize during the intense forming process. It is suitable for coatings that can be directly painted without further treatment except general cleaning.

Defect

The main reasons are: shedding, scratches, passivation spots, zinc particles, thick edges, air knife streaks, air knife scratches, exposed steel, inclusions, mechanical damage, poor steel base performance, wave edges, buckling, size mismatch, stamping, zinc layer thickness mismatch, roller marks, etc.

The main reasons for zinc layer shedding are: surface oxidation, silicon compounds, dirty cold rolling emulsion, too high dew point of oxidation atmosphere and protective gas in NOF section, unreasonable air-fuel ratio, low hydrogen flow, oxygen infiltration in the furnace, low temperature of strip entering the pot, low furnace pressure in RWP section and furnace door suction, low furnace temperature in NOF section, incomplete evaporation of grease, low aluminum content in zinc pot, too fast unit speed, insufficient reduction, too short residence time in zinc liquid, and thick coating.

Products

Related Products

Product Parameters

Product Name | Galvanized Steel Coil |

Package | 3 layers of packing. Inside is craft paper, middle is waterproof plastic film and outside GI steel sheet to be covered by steel |

Grade | spcc DX51D DX52D DX53D DX54D +Z S220GD, S280GD, S350GD |

Zinc coating | Z30-275G/M2 |

Surface Treatment | light Oil,Unoil,dry,chromate passivated,non-chromate passivated |

Thickness | 0.12-4mm |

Spangle | Regular, Minimal, Zero, Big, Small |

Plating definition

(1) Spangle coating

During the normal solidification process of the zinc layer, the zinc grains grow freely to form a coating with obvious spangle morphology.

(2) Minimized spangle coating

During the solidification process of the zinc layer, the zinc grains are artificially restricted to form a spangle coating as small as possible.

(3) Spangle-free coating

A coating obtained by adjusting the chemical composition of the plating solution, which has no visible spangle morphology and a uniform surface.

(4) Zinc-iron alloy coating

The steel strip after passing through the galvanizing tank is heat treated to form an alloy layer of zinc and iron. This coating has a dark gray appearance and no metallic luster. It is easy to powderize during the intense forming process. It is suitable for coatings that can be directly painted without further treatment except general cleaning.

During the normal solidification process of the zinc layer, the zinc grains grow freely to form a coating with obvious spangle morphology.

(2) Minimized spangle coating

During the solidification process of the zinc layer, the zinc grains are artificially restricted to form a spangle coating as small as possible.

(3) Spangle-free coating

A coating obtained by adjusting the chemical composition of the plating solution, which has no visible spangle morphology and a uniform surface.

(4) Zinc-iron alloy coating

The steel strip after passing through the galvanizing tank is heat treated to form an alloy layer of zinc and iron. This coating has a dark gray appearance and no metallic luster. It is easy to powderize during the intense forming process. It is suitable for coatings that can be directly painted without further treatment except general cleaning.

Defect

The main reasons are: shedding, scratches, passivation spots, zinc particles, thick edges, air knife streaks, air knife scratches, exposed steel, inclusions, mechanical damage, poor steel base performance, wave edges, buckling, size mismatch, stamping, zinc layer thickness mismatch, roller marks, etc.

The main reasons for zinc layer shedding are: surface oxidation, silicon compounds, dirty cold rolling emulsion, too high dew point of oxidation atmosphere and protective gas in NOF section, unreasonable air-fuel ratio, low hydrogen flow, oxygen infiltration in the furnace, low temperature of strip entering the pot, low furnace pressure in RWP section and furnace door suction, low furnace temperature in NOF section, incomplete evaporation of grease, low aluminum content in zinc pot, too fast unit speed, insufficient reduction, too short residence time in zinc liquid, and thick coating.