- +86 188 5310 8009

- info@northchinametal.com

- Shuntai North Road, High-tech Zone, Jinan City, Shandong Province

Call Us

Mail To

Address

Shuntai North Road, High-tech Zone, Jinan City, Shandong Province

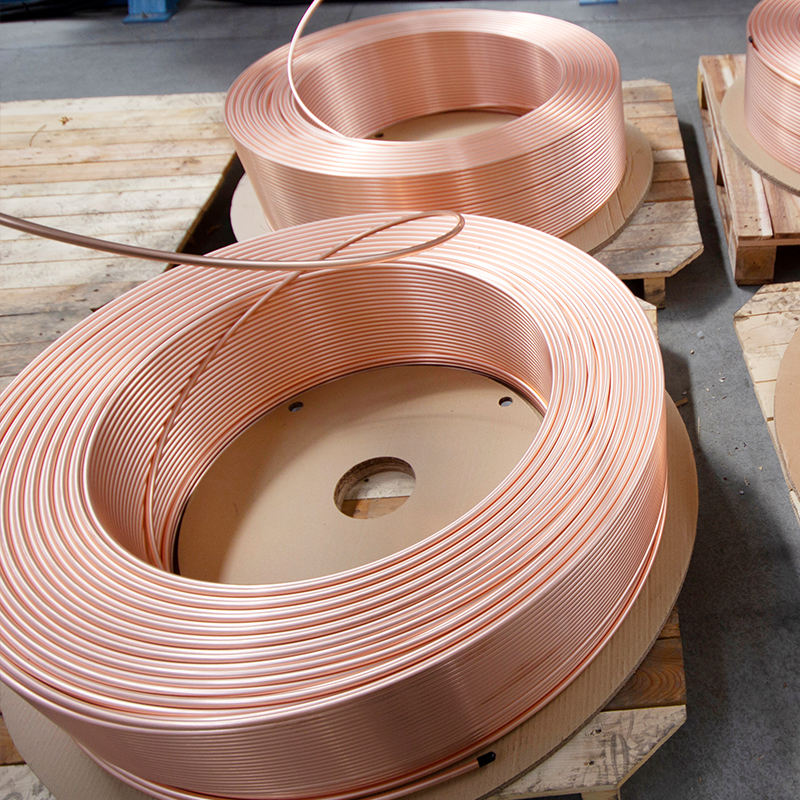

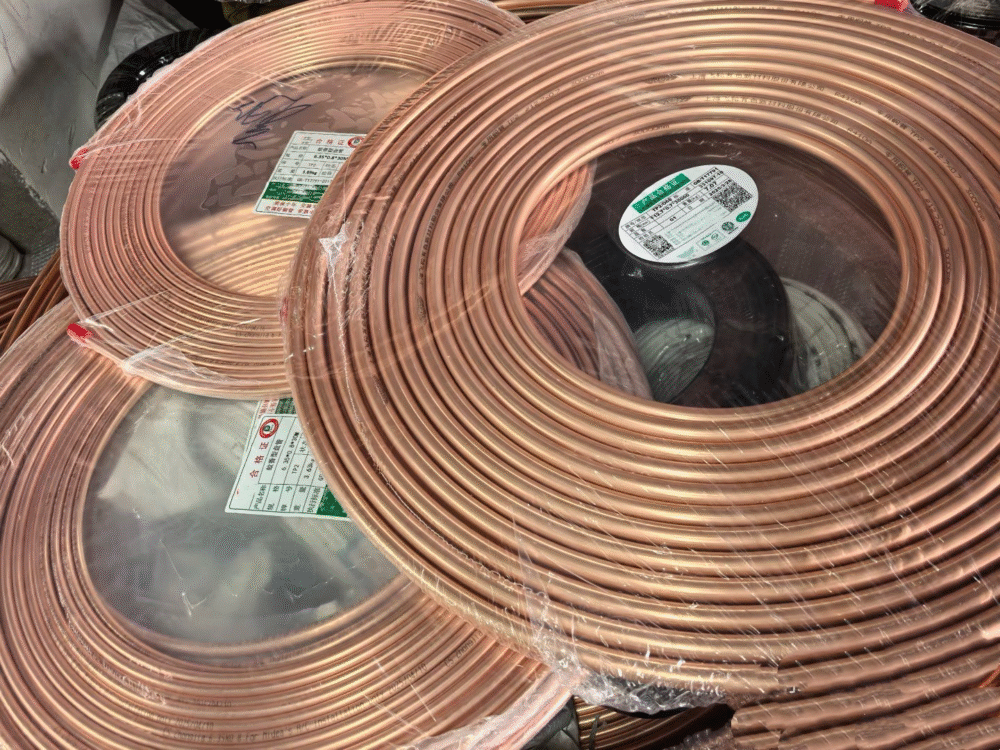

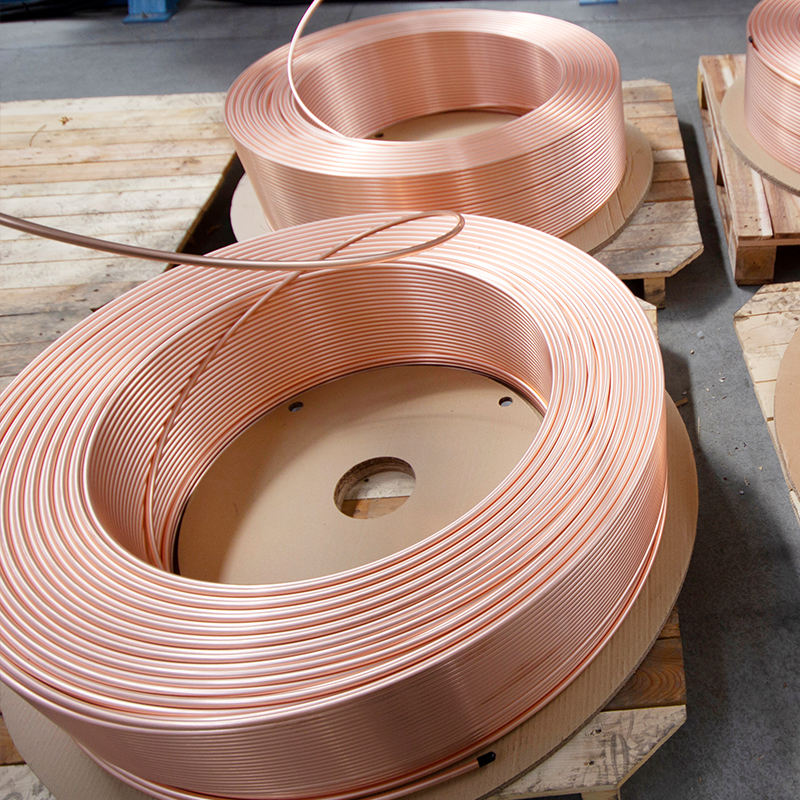

Air conditioner copper pipe pancake coil copper pipe (Copy)

Copper tubing (also known as copper pipe) is a type of seamless non-ferrous metal tubing that is pressed or drawn. It is mainly used in building hot and cold water systems, heating and cooling pipelines, conductive and heat dissipation components for electronic products, as well as industrial applications such as heat exchange equipment, oxygen production equipment, and hydraulic systems. It is characterized by its light weight, excellent thermal and electrical conductivity, corrosion resistance, and resistance to high temperatures and pressures (melting point up to 1083℃).

Product Parameters

| Whether alloy | non-alloy | Minimum copper content | 99.9% |

| Elongation (≥ %) | 40 | Type | Circular coil copper tube |

| Tensile strength (≥ MPa) | 315 | Country of origin | Shandong, China |

| Product name | Pancake copper tube | application | For air conditioning or refrigerators |

| Material | 99.9% copper pipe | length | Customizable |

| Outer diameter | 4.76 – 22.22 mm | Processing services | Bending, uncoiling, welding, punching, cutting |

| Specification | C12200 | wall thickness | 0.3 mm – 30 mm |

Chemical composition

| Copper Tubing Sizes (CTS) for Plumbing[4] | ||||

|---|---|---|---|---|

| Nominal size | Outside diameter (OD) [in (mm)] | Inside diameter (ID) [in (mm)] | ||

| Type K | Type L | Type M | ||

| 1⁄4 | 3⁄8 (9.5) | 0.305 (7.747) | 0.315 (8.001) | |

| 3⁄8 | 1⁄2 (12.7) | 0.402 (10.211) | 0.430 (10.922) | 0.450 (11.430) |

| 1⁄2 | 5⁄8 (15.875) | 0.528 (13.411) | 0.545 (13.843) | 0.569 (14.453) |

| 5⁄8 | 3⁄4 (19.05) | 0.652 (16.561) | 0.668 (16.967) | 0.690 (17.526) |

| 3⁄4 | 7⁄8 (22.225) | 0.745 (18.923) | 0.785 (19.939) | 0.811 (20.599) |

| 1 | 1+1⁄8 (28.575) | 0.995 (25.273) | 1.025 (26.035) | 1.055 (26.797) |

| 11⁄4 | 1+3⁄8 (34.925) | 1.245 (31.623) | 1.265 (32.131) | 1.291 (32.791) |

| 11⁄2 | 1+5⁄8 (41.275) | 1.481 (37.617) | 1.505 (38.227) | 1.527 (38.786) |

| 2 | 2+1⁄8 (53.975) | 1.959 (49.759) | 1.985 (50.419) | 2.009 (51.029) |

| 21⁄2 | 2+5⁄8 (66.675) | 2.435 (61.849) | 2.465 (62.611) | 2.495 (63.373) |

| 3 | 3+1⁄8 (79.375) | 2.907 (73.838) | 2.945 (74.803) | 2.981 (75.717) |

Standard Copper Tubes Wall Thicknesses for Different Uses

Copper pipes commonly used in piping systems can be divided into two typical categories based on their application.

In the refrigeration and air conditioning industry, copper pipes are mainly made of pure copper, with the TP2 grade being most prevalent for indoor air conditioner connection lines. The typical diameter range is 3 to 19 mm, with wall thicknesses divided into three national standard levels:

- Standard pipes: Minimum 0.46 mm

- Thin-walled pipes: Starting from 0.30 mm

- Thick-walled pipes: Up to 0.81 mm

Threaded copper pipes with a diameter of 9.5 mm are commonly used in split-type air conditioners, where the thin-walled model is about 0.4 mm thick.

For domestic water supply and drainage systems, copper water pipes are widely used, with diameters similar to PPR pipes. National standards require the pipe to meet pressure-bearing requirements.

Taking DN15 copper pipe as an example:

- Thin-walled models with a 1 mm wall thickness are suitable for low-rise residential buildings.

- For mid-rise buildings, a reinforced type with 1.5 mm wall thickness is used.

- For main water supply lines in buildings, a strengthened type with wall thickness above 2 mm is typical.

In new hospitals, international grade C122 is often selected, and DN20 hot water pipes commonly use a 2.5 mm wall thickness.

Copper condenser fittings for appliances follow multiple standards. For example, the internationally accepted specification for 9 mm diameter copper pipe takes into account the charging pressure of refrigerants, and the industry generally recommends a wall thickness between 1.2 and 1.8 mm. In U.S. HVAC codes, the high-pressure HW type in R410A systems must use a 2.0 mm standard thickness to pass burst tests.

Industrial circulation systems require special selections. In one petrochemical plant’s reflux unit, a 76 mm diameter heat-conducting copper pipe was produced with a 3.5 mm ultra-thick wall via cold rolling to withstand scouring by 12 m/s flow rates. In new energy vehicles, bimetallic copper pipes with composite inner linings are used in electronic circulation cooling, with a base copper layer of 1.2 mm covered by reinforcement, achieving a 34% weight reduction.

European Union building standards have dedicated classifications. For example, Type-A flanged drinking water pipes with a 14 mm diameter require a tested wall thickness of no less than 1.85 mm and a weight tolerance limit of 7%. For medical-grade gas delivery, special requirements specify that the wall thickness tolerance for straight pipes made from dual-phase copper must be within 0.06 mm.

Attention to selection standards in practical use is important. In one wastewater treatment project, ammonia removal system rework revealed that pressure failure occurred because the owner illegally substituted 0.5 mm thick refrigeration pipe for the standard TP2 high-pressure water pipe. In another project acceptance meeting, supervision pointed out that the product certificate provided by the installer showed wall thickness deviation exceeding the GB code by 5%, leading to the material being ruled non-compliant.

Material mechanical properties result in differing outcomes. One testing laboratory showed that 0.8 mm thick forged seamless steel pipes reached the crack resistance grade of 1.5 mm laser-welded pipes. It is recommended that for high-temperature pipelines subject to complex cyclic stresses, thin-walled, high-strength copper pipes manufactured by precision forging processes should be prioritized. Users should determine the optimal wall thickness range based on the fluid’s corrosiveness, pressure values, and service life requirements, consulting authoritative industry selection tables for accurate data.

How To Measure/Determine Copper Pipe/Tube Size?

There are a few reliable methods to determine copper pipe size:

- Check Pipe Markings:

Many pipes have size and thickness printed or stamped along their length. - Measure Outside Diameter (OD):

Use a tape measure or caliper to measure the OD. For example, a pipe with a 28.6 mm OD is typically a 1-1/8 inch copper pipe. - Measure Circumference:

Wrap a tape measure around the pipe to get the circumference, then divide by π (3.14) to find the diameter.- Example: A 90 mm circumference ÷ 3.14 = 28.6 mm OD.

- Check Inner Diameter (ID):

For plumbing, the nominal size is often close to the internal diameter—measure across the pipe opening from inside wall to inside wall. - Reference the Weight:

Sometimes, the weight per meter helps confirm the size.

What is the Most Common Copper Pipe Size?

In residential water supply systems, the most frequently used copper pipe sizes are:

- 1/2 inch (15 mm OD): Common for branch lines to individual fixtures.

- 3/4 inch (22 mm OD): Often used for main supply lines and larger branches.

- 1 inch (28 mm OD): Used for main lines in larger homes or where higher demand exists.

These sizes are practical for most household needs, balancing ease of installation and adequate flow.

What Size Copper Pipe for Shower?

For a typical shower, a 1/2 inch copper pipe is usually sufficient, as it can handle up to 4 fixture units (according to the Uniform Plumbing Code). If the shower features high-flow heads or multiple outlets, or if the run is unusually long, a 3/4 inch supply may be recommended for optimal pressure.

What Size Copper Pipe for Water Lines?

- Branch lines to fixtures (sink, toilet, shower):

1/2 inch is standard. - Main water supply line:

3/4 inch is common for most homes; 1 inch may be needed for larger houses or higher demand. - Commercial or multi-unit buildings:

Larger sizes (1 inch and up) are used for main supplies.

Sizing should also account for the total number of fixtures, developed length of piping, elevation changes, and available water pressure.

Description

Product Parameters

| Whether alloy | non-alloy | Minimum copper content | 99.9% |

| Elongation (≥ %) | 40 | Type | Circular coil copper tube |

| Tensile strength (≥ MPa) | 315 | Country of origin | Shandong, China |

| Product name | Pancake copper tube | application | For air conditioning or refrigerators |

| Material | 99.9% copper pipe | length | Customizable |

| Outer diameter | 4.76 – 22.22 mm | Processing services | Bending, uncoiling, welding, punching, cutting |

| Specification | C12200 | wall thickness | 0.3 mm – 30 mm |

Chemical composition

| Copper Tubing Sizes (CTS) for Plumbing[4] | ||||

|---|---|---|---|---|

| Nominal size | Outside diameter (OD) [in (mm)] | Inside diameter (ID) [in (mm)] | ||

| Type K | Type L | Type M | ||

| 1⁄4 | 3⁄8 (9.5) | 0.305 (7.747) | 0.315 (8.001) | |

| 3⁄8 | 1⁄2 (12.7) | 0.402 (10.211) | 0.430 (10.922) | 0.450 (11.430) |

| 1⁄2 | 5⁄8 (15.875) | 0.528 (13.411) | 0.545 (13.843) | 0.569 (14.453) |

| 5⁄8 | 3⁄4 (19.05) | 0.652 (16.561) | 0.668 (16.967) | 0.690 (17.526) |

| 3⁄4 | 7⁄8 (22.225) | 0.745 (18.923) | 0.785 (19.939) | 0.811 (20.599) |

| 1 | 1+1⁄8 (28.575) | 0.995 (25.273) | 1.025 (26.035) | 1.055 (26.797) |

| 11⁄4 | 1+3⁄8 (34.925) | 1.245 (31.623) | 1.265 (32.131) | 1.291 (32.791) |

| 11⁄2 | 1+5⁄8 (41.275) | 1.481 (37.617) | 1.505 (38.227) | 1.527 (38.786) |

| 2 | 2+1⁄8 (53.975) | 1.959 (49.759) | 1.985 (50.419) | 2.009 (51.029) |

| 21⁄2 | 2+5⁄8 (66.675) | 2.435 (61.849) | 2.465 (62.611) | 2.495 (63.373) |

| 3 | 3+1⁄8 (79.375) | 2.907 (73.838) | 2.945 (74.803) | 2.981 (75.717) |

Standard Copper Tubes Wall Thicknesses for Different Uses

Copper pipes commonly used in piping systems can be divided into two typical categories based on their application.

In the refrigeration and air conditioning industry, copper pipes are mainly made of pure copper, with the TP2 grade being most prevalent for indoor air conditioner connection lines. The typical diameter range is 3 to 19 mm, with wall thicknesses divided into three national standard levels:

- Standard pipes: Minimum 0.46 mm

- Thin-walled pipes: Starting from 0.30 mm

- Thick-walled pipes: Up to 0.81 mm

Threaded copper pipes with a diameter of 9.5 mm are commonly used in split-type air conditioners, where the thin-walled model is about 0.4 mm thick.

For domestic water supply and drainage systems, copper water pipes are widely used, with diameters similar to PPR pipes. National standards require the pipe to meet pressure-bearing requirements.

Taking DN15 copper pipe as an example:

- Thin-walled models with a 1 mm wall thickness are suitable for low-rise residential buildings.

- For mid-rise buildings, a reinforced type with 1.5 mm wall thickness is used.

- For main water supply lines in buildings, a strengthened type with wall thickness above 2 mm is typical.

In new hospitals, international grade C122 is often selected, and DN20 hot water pipes commonly use a 2.5 mm wall thickness.

Copper condenser fittings for appliances follow multiple standards. For example, the internationally accepted specification for 9 mm diameter copper pipe takes into account the charging pressure of refrigerants, and the industry generally recommends a wall thickness between 1.2 and 1.8 mm. In U.S. HVAC codes, the high-pressure HW type in R410A systems must use a 2.0 mm standard thickness to pass burst tests.

Industrial circulation systems require special selections. In one petrochemical plant’s reflux unit, a 76 mm diameter heat-conducting copper pipe was produced with a 3.5 mm ultra-thick wall via cold rolling to withstand scouring by 12 m/s flow rates. In new energy vehicles, bimetallic copper pipes with composite inner linings are used in electronic circulation cooling, with a base copper layer of 1.2 mm covered by reinforcement, achieving a 34% weight reduction.

European Union building standards have dedicated classifications. For example, Type-A flanged drinking water pipes with a 14 mm diameter require a tested wall thickness of no less than 1.85 mm and a weight tolerance limit of 7%. For medical-grade gas delivery, special requirements specify that the wall thickness tolerance for straight pipes made from dual-phase copper must be within 0.06 mm.

Attention to selection standards in practical use is important. In one wastewater treatment project, ammonia removal system rework revealed that pressure failure occurred because the owner illegally substituted 0.5 mm thick refrigeration pipe for the standard TP2 high-pressure water pipe. In another project acceptance meeting, supervision pointed out that the product certificate provided by the installer showed wall thickness deviation exceeding the GB code by 5%, leading to the material being ruled non-compliant.

Material mechanical properties result in differing outcomes. One testing laboratory showed that 0.8 mm thick forged seamless steel pipes reached the crack resistance grade of 1.5 mm laser-welded pipes. It is recommended that for high-temperature pipelines subject to complex cyclic stresses, thin-walled, high-strength copper pipes manufactured by precision forging processes should be prioritized. Users should determine the optimal wall thickness range based on the fluid’s corrosiveness, pressure values, and service life requirements, consulting authoritative industry selection tables for accurate data.

How To Measure/Determine Copper Pipe/Tube Size?

There are a few reliable methods to determine copper pipe size:

- Check Pipe Markings:

Many pipes have size and thickness printed or stamped along their length. - Measure Outside Diameter (OD):

Use a tape measure or caliper to measure the OD. For example, a pipe with a 28.6 mm OD is typically a 1-1/8 inch copper pipe. - Measure Circumference:

Wrap a tape measure around the pipe to get the circumference, then divide by π (3.14) to find the diameter.- Example: A 90 mm circumference ÷ 3.14 = 28.6 mm OD.

- Check Inner Diameter (ID):

For plumbing, the nominal size is often close to the internal diameter—measure across the pipe opening from inside wall to inside wall. - Reference the Weight:

Sometimes, the weight per meter helps confirm the size.

What is the Most Common Copper Pipe Size?

In residential water supply systems, the most frequently used copper pipe sizes are:

- 1/2 inch (15 mm OD): Common for branch lines to individual fixtures.

- 3/4 inch (22 mm OD): Often used for main supply lines and larger branches.

- 1 inch (28 mm OD): Used for main lines in larger homes or where higher demand exists.

These sizes are practical for most household needs, balancing ease of installation and adequate flow.

What Size Copper Pipe for Shower?

For a typical shower, a 1/2 inch copper pipe is usually sufficient, as it can handle up to 4 fixture units (according to the Uniform Plumbing Code). If the shower features high-flow heads or multiple outlets, or if the run is unusually long, a 3/4 inch supply may be recommended for optimal pressure.

What Size Copper Pipe for Water Lines?

- Branch lines to fixtures (sink, toilet, shower):

1/2 inch is standard. - Main water supply line:

3/4 inch is common for most homes; 1 inch may be needed for larger houses or higher demand. - Commercial or multi-unit buildings:

Larger sizes (1 inch and up) are used for main supplies.

Sizing should also account for the total number of fixtures, developed length of piping, elevation changes, and available water pressure.

Products

Related Products

Product Parameters

| Whether alloy | non-alloy | Minimum copper content | 99.9% |

| Elongation (≥ %) | 40 | Type | Circular coil copper tube |

| Tensile strength (≥ MPa) | 315 | Country of origin | Shandong, China |

| Product name | Pancake copper tube | application | For air conditioning or refrigerators |

| Material | 99.9% copper pipe | length | Customizable |

| Outer diameter | 4.76 – 22.22 mm | Processing services | Bending, uncoiling, welding, punching, cutting |

| Specification | C12200 | wall thickness | 0.3 mm – 30 mm |

Chemical composition

| Copper Tubing Sizes (CTS) for Plumbing[4] | ||||

|---|---|---|---|---|

| Nominal size | Outside diameter (OD) [in (mm)] | Inside diameter (ID) [in (mm)] | ||

| Type K | Type L | Type M | ||

| 1⁄4 | 3⁄8 (9.5) | 0.305 (7.747) | 0.315 (8.001) | |

| 3⁄8 | 1⁄2 (12.7) | 0.402 (10.211) | 0.430 (10.922) | 0.450 (11.430) |

| 1⁄2 | 5⁄8 (15.875) | 0.528 (13.411) | 0.545 (13.843) | 0.569 (14.453) |

| 5⁄8 | 3⁄4 (19.05) | 0.652 (16.561) | 0.668 (16.967) | 0.690 (17.526) |

| 3⁄4 | 7⁄8 (22.225) | 0.745 (18.923) | 0.785 (19.939) | 0.811 (20.599) |

| 1 | 1+1⁄8 (28.575) | 0.995 (25.273) | 1.025 (26.035) | 1.055 (26.797) |

| 11⁄4 | 1+3⁄8 (34.925) | 1.245 (31.623) | 1.265 (32.131) | 1.291 (32.791) |

| 11⁄2 | 1+5⁄8 (41.275) | 1.481 (37.617) | 1.505 (38.227) | 1.527 (38.786) |

| 2 | 2+1⁄8 (53.975) | 1.959 (49.759) | 1.985 (50.419) | 2.009 (51.029) |

| 21⁄2 | 2+5⁄8 (66.675) | 2.435 (61.849) | 2.465 (62.611) | 2.495 (63.373) |

| 3 | 3+1⁄8 (79.375) | 2.907 (73.838) | 2.945 (74.803) | 2.981 (75.717) |

Standard Copper Tubes Wall Thicknesses for Different Uses

Copper pipes commonly used in piping systems can be divided into two typical categories based on their application.

In the refrigeration and air conditioning industry, copper pipes are mainly made of pure copper, with the TP2 grade being most prevalent for indoor air conditioner connection lines. The typical diameter range is 3 to 19 mm, with wall thicknesses divided into three national standard levels:

- Standard pipes: Minimum 0.46 mm

- Thin-walled pipes: Starting from 0.30 mm

- Thick-walled pipes: Up to 0.81 mm

Threaded copper pipes with a diameter of 9.5 mm are commonly used in split-type air conditioners, where the thin-walled model is about 0.4 mm thick.

For domestic water supply and drainage systems, copper water pipes are widely used, with diameters similar to PPR pipes. National standards require the pipe to meet pressure-bearing requirements.

Taking DN15 copper pipe as an example:

- Thin-walled models with a 1 mm wall thickness are suitable for low-rise residential buildings.

- For mid-rise buildings, a reinforced type with 1.5 mm wall thickness is used.

- For main water supply lines in buildings, a strengthened type with wall thickness above 2 mm is typical.

In new hospitals, international grade C122 is often selected, and DN20 hot water pipes commonly use a 2.5 mm wall thickness.

Copper condenser fittings for appliances follow multiple standards. For example, the internationally accepted specification for 9 mm diameter copper pipe takes into account the charging pressure of refrigerants, and the industry generally recommends a wall thickness between 1.2 and 1.8 mm. In U.S. HVAC codes, the high-pressure HW type in R410A systems must use a 2.0 mm standard thickness to pass burst tests.

Industrial circulation systems require special selections. In one petrochemical plant’s reflux unit, a 76 mm diameter heat-conducting copper pipe was produced with a 3.5 mm ultra-thick wall via cold rolling to withstand scouring by 12 m/s flow rates. In new energy vehicles, bimetallic copper pipes with composite inner linings are used in electronic circulation cooling, with a base copper layer of 1.2 mm covered by reinforcement, achieving a 34% weight reduction.

European Union building standards have dedicated classifications. For example, Type-A flanged drinking water pipes with a 14 mm diameter require a tested wall thickness of no less than 1.85 mm and a weight tolerance limit of 7%. For medical-grade gas delivery, special requirements specify that the wall thickness tolerance for straight pipes made from dual-phase copper must be within 0.06 mm.

Attention to selection standards in practical use is important. In one wastewater treatment project, ammonia removal system rework revealed that pressure failure occurred because the owner illegally substituted 0.5 mm thick refrigeration pipe for the standard TP2 high-pressure water pipe. In another project acceptance meeting, supervision pointed out that the product certificate provided by the installer showed wall thickness deviation exceeding the GB code by 5%, leading to the material being ruled non-compliant.

Material mechanical properties result in differing outcomes. One testing laboratory showed that 0.8 mm thick forged seamless steel pipes reached the crack resistance grade of 1.5 mm laser-welded pipes. It is recommended that for high-temperature pipelines subject to complex cyclic stresses, thin-walled, high-strength copper pipes manufactured by precision forging processes should be prioritized. Users should determine the optimal wall thickness range based on the fluid’s corrosiveness, pressure values, and service life requirements, consulting authoritative industry selection tables for accurate data.

How To Measure/Determine Copper Pipe/Tube Size?

There are a few reliable methods to determine copper pipe size:

- Check Pipe Markings:

Many pipes have size and thickness printed or stamped along their length. - Measure Outside Diameter (OD):

Use a tape measure or caliper to measure the OD. For example, a pipe with a 28.6 mm OD is typically a 1-1/8 inch copper pipe. - Measure Circumference:

Wrap a tape measure around the pipe to get the circumference, then divide by π (3.14) to find the diameter.- Example: A 90 mm circumference ÷ 3.14 = 28.6 mm OD.

- Check Inner Diameter (ID):

For plumbing, the nominal size is often close to the internal diameter—measure across the pipe opening from inside wall to inside wall. - Reference the Weight:

Sometimes, the weight per meter helps confirm the size.

What is the Most Common Copper Pipe Size?

In residential water supply systems, the most frequently used copper pipe sizes are:

- 1/2 inch (15 mm OD): Common for branch lines to individual fixtures.

- 3/4 inch (22 mm OD): Often used for main supply lines and larger branches.

- 1 inch (28 mm OD): Used for main lines in larger homes or where higher demand exists.

These sizes are practical for most household needs, balancing ease of installation and adequate flow.

What Size Copper Pipe for Shower?

For a typical shower, a 1/2 inch copper pipe is usually sufficient, as it can handle up to 4 fixture units (according to the Uniform Plumbing Code). If the shower features high-flow heads or multiple outlets, or if the run is unusually long, a 3/4 inch supply may be recommended for optimal pressure.

What Size Copper Pipe for Water Lines?

- Branch lines to fixtures (sink, toilet, shower):

1/2 inch is standard. - Main water supply line:

3/4 inch is common for most homes; 1 inch may be needed for larger houses or higher demand. - Commercial or multi-unit buildings:

Larger sizes (1 inch and up) are used for main supplies.

Sizing should also account for the total number of fixtures, developed length of piping, elevation changes, and available water pressure.