- +86 188 5310 8009

- info@northchinametal.com

- Shuntai North Road, High-tech Zone, Jinan City, Shandong Province

Call Us

Mail To

Address

Shuntai North Road, High-tech Zone, Jinan City, Shandong Province

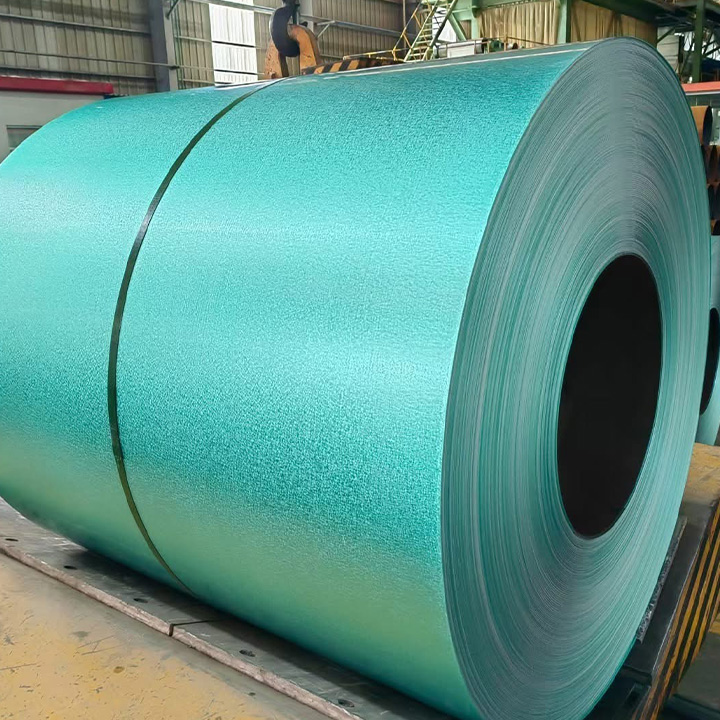

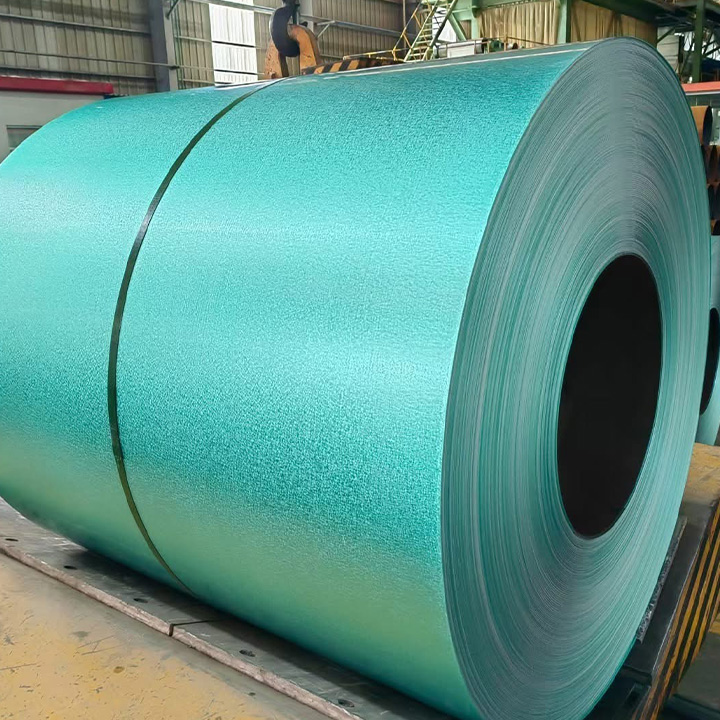

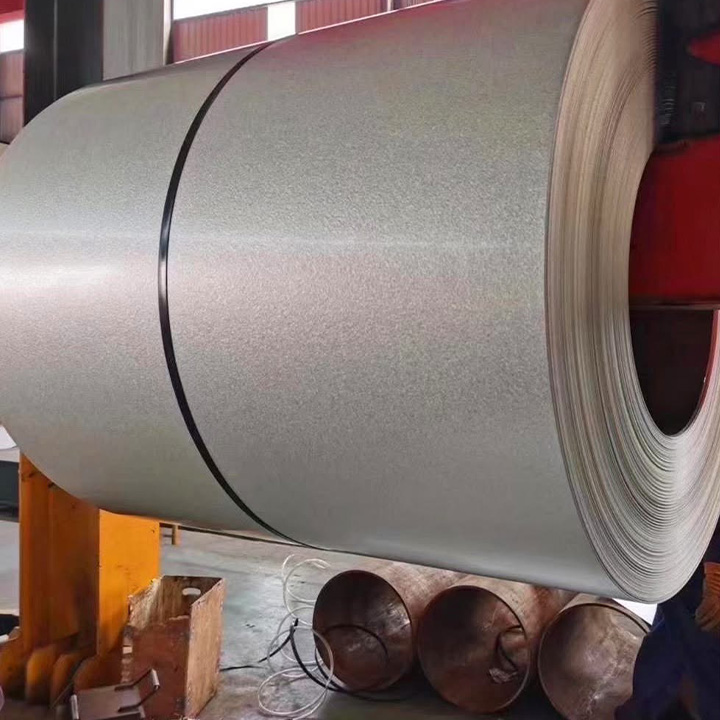

PPGL steel coil

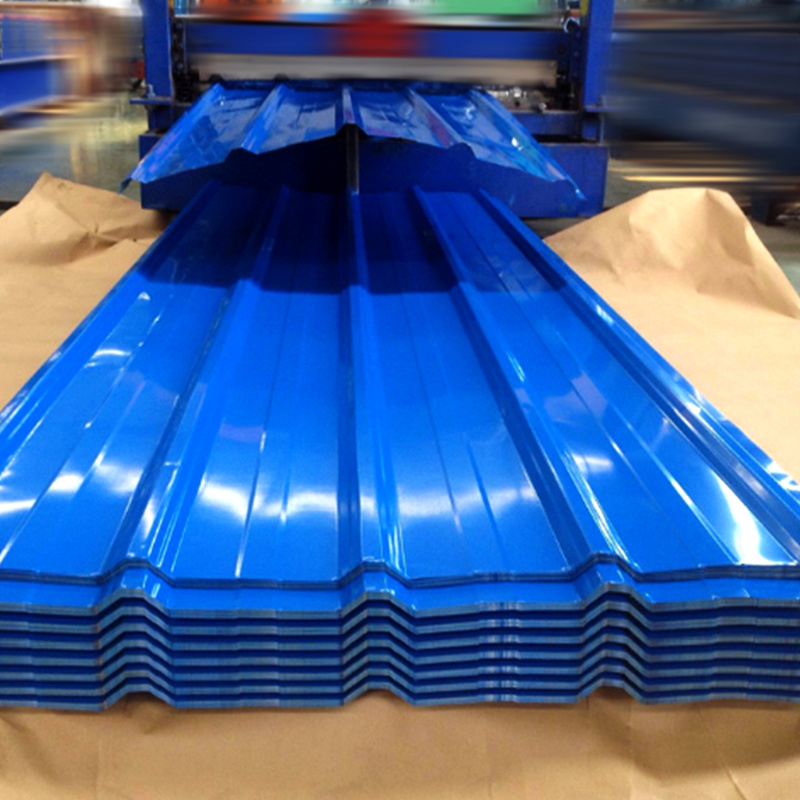

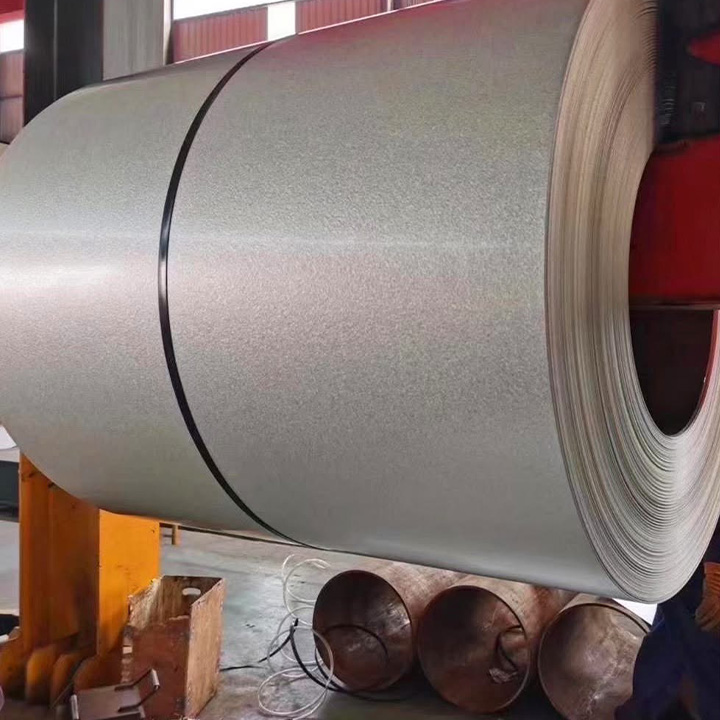

Color coated steel coil is a product made of hot-dip galvanized steel sheet, hot-dip aluminum-zinc steel sheet, electro-galvanized steel sheet, etc. After surface pretreatment (chemical degreasing and chemical conversion treatment), one or several layers of organic coating are applied on the surface, and then cured by baking. It is named after the colored steel coils coated with various colors of organic coatings, and is referred to as color coated steel coils.

Technical Standard | EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

Steel Grade | DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, SECC, |

Base Steel | Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel |

Thickness | 0.12mm-3.0mm |

Width | 1200/1000/600(width before corrugation) |

Length | Recommand to fit for the container length,within5.5m(20ft), |

Zinc Coating | Z30-275g/sqm |

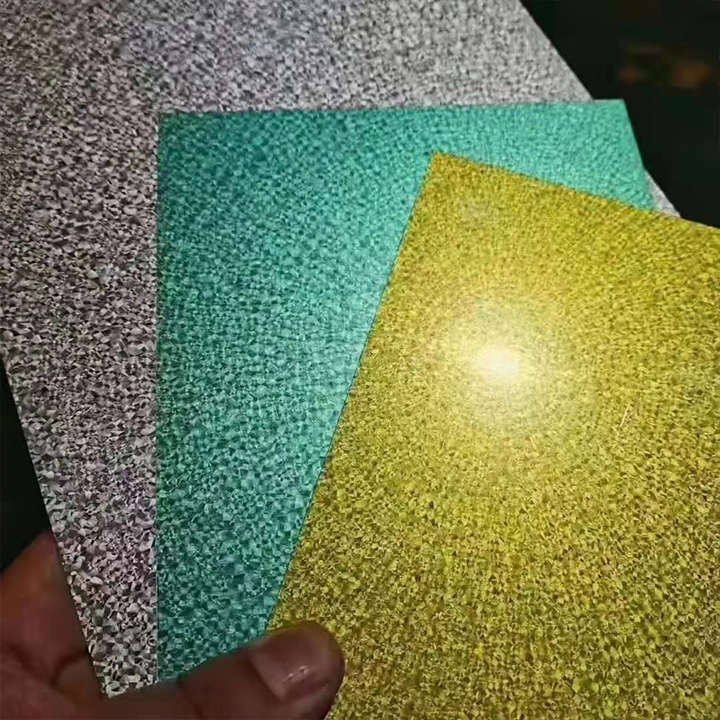

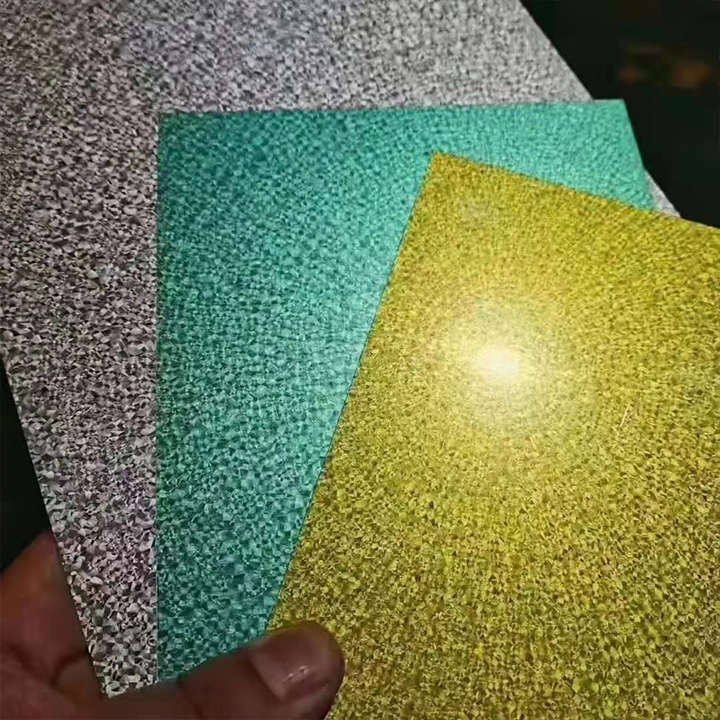

Coating Color | ALL RAL Cards Color,or according to customer’s sample |

Color coated coil substrate classification

Hot-dip galvanized substrate

The product obtained by applying organic coating on hot-dip galvanized steel sheet is hot-dip galvanized color-coated sheet. In addition to the protective effect of zinc, the organic coating on the surface of hot-dip galvanized color-coated sheet also plays a role in isolation protection and rust prevention, and its service life is longer than that of hot-dip galvanized sheet. The zinc content of hot-dip galvanized substrate is generally 180g/m2 (double-sided), and the maximum zinc content of hot-dip galvanized substrate for building exterior is 275g/m2.

Hot-dip aluminum-zinc substrate

Hot-dip aluminum-zinc steel sheet (55% Al-Zn) is used as the new coating substrate, usually containing 150g/㎡ of aluminum and zinc (double-sided). The corrosion resistance of hot-dip aluminum-zinc sheet is 2-5 times that of hot-dip galvanized sheet. Continuous or intermittent use at temperatures up to 490℃ will not cause serious oxidation or scale. The ability to reflect heat and light is twice that of hot-dip galvanized steel sheet, and the reflectivity is greater than 0.75, making it an ideal building material for saving energy.

Electrogalvanized substrate

The product obtained by using electrogalvanized sheet as substrate, coating with organic coating and baking is electrogalvanized color-coated sheet. Since the zinc layer of electrogalvanized sheet is thin, the zinc content is usually 20/20g/m2, so this product is not suitable for outdoor use in making walls, roofs, etc. However, due to its beautiful appearance and excellent processing performance, it can be mainly used in home appliances, audio, steel furniture, interior decoration, etc.

Color coated coil coating types

Polyester

Good adhesion, rich colors, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon-modified polyester

i.e. (SMP), good hardness, wear resistance and heat resistance of the coating, as well as good exterior durability and resistance to chalking, gloss retention, average flexibility, medium cost.

High-durability polyester

i.e. (HDP), excellent color retention and UV resistance, excellent outdoor durability and resistance to chalking, good film adhesion, rich colors, excellent cost performance.

Polyvinylidene fluoride

i.e. (PVDF), excellent color retention and UV resistance, excellent outdoor durability and resistance to chalking, excellent solvent resistance, good formability, dirt resistance, limited colors, high cost.

Description

Technical Standard | EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

Steel Grade | DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, SECC, |

Base Steel | Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel |

Thickness | 0.12mm-3.0mm |

Width | 1200/1000/600(width before corrugation) |

Length | Recommand to fit for the container length,within5.5m(20ft), |

Zinc Coating | Z30-275g/sqm |

Coating Color | ALL RAL Cards Color,or according to customer’s sample |

Color coated coil substrate classification

Hot-dip galvanized substrate

The product obtained by applying organic coating on hot-dip galvanized steel sheet is hot-dip galvanized color-coated sheet. In addition to the protective effect of zinc, the organic coating on the surface of hot-dip galvanized color-coated sheet also plays a role in isolation protection and rust prevention, and its service life is longer than that of hot-dip galvanized sheet. The zinc content of hot-dip galvanized substrate is generally 180g/m2 (double-sided), and the maximum zinc content of hot-dip galvanized substrate for building exterior is 275g/m2.

Hot-dip aluminum-zinc substrate

Hot-dip aluminum-zinc steel sheet (55% Al-Zn) is used as the new coating substrate, usually containing 150g/㎡ of aluminum and zinc (double-sided). The corrosion resistance of hot-dip aluminum-zinc sheet is 2-5 times that of hot-dip galvanized sheet. Continuous or intermittent use at temperatures up to 490℃ will not cause serious oxidation or scale. The ability to reflect heat and light is twice that of hot-dip galvanized steel sheet, and the reflectivity is greater than 0.75, making it an ideal building material for saving energy.

Electrogalvanized substrate

The product obtained by using electrogalvanized sheet as substrate, coating with organic coating and baking is electrogalvanized color-coated sheet. Since the zinc layer of electrogalvanized sheet is thin, the zinc content is usually 20/20g/m2, so this product is not suitable for outdoor use in making walls, roofs, etc. However, due to its beautiful appearance and excellent processing performance, it can be mainly used in home appliances, audio, steel furniture, interior decoration, etc.

Color coated coil coating types

Polyester

Good adhesion, rich colors, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon-modified polyester

i.e. (SMP), good hardness, wear resistance and heat resistance of the coating, as well as good exterior durability and resistance to chalking, gloss retention, average flexibility, medium cost.

High-durability polyester

i.e. (HDP), excellent color retention and UV resistance, excellent outdoor durability and resistance to chalking, good film adhesion, rich colors, excellent cost performance.

Polyvinylidene fluoride

i.e. (PVDF), excellent color retention and UV resistance, excellent outdoor durability and resistance to chalking, excellent solvent resistance, good formability, dirt resistance, limited colors, high cost.

Products

Related Products

Related products

Technical Standard | EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

Steel Grade | DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, SECC, |

Base Steel | Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel |

Thickness | 0.12mm-3.0mm |

Width | 1200/1000/600(width before corrugation) |

Length | Recommand to fit for the container length,within5.5m(20ft), |

Zinc Coating | Z30-275g/sqm |

Coating Color | ALL RAL Cards Color,or according to customer’s sample |

Color coated coil substrate classification

Hot-dip galvanized substrate

The product obtained by applying organic coating on hot-dip galvanized steel sheet is hot-dip galvanized color-coated sheet. In addition to the protective effect of zinc, the organic coating on the surface of hot-dip galvanized color-coated sheet also plays a role in isolation protection and rust prevention, and its service life is longer than that of hot-dip galvanized sheet. The zinc content of hot-dip galvanized substrate is generally 180g/m2 (double-sided), and the maximum zinc content of hot-dip galvanized substrate for building exterior is 275g/m2.

Hot-dip aluminum-zinc substrate

Hot-dip aluminum-zinc steel sheet (55% Al-Zn) is used as the new coating substrate, usually containing 150g/㎡ of aluminum and zinc (double-sided). The corrosion resistance of hot-dip aluminum-zinc sheet is 2-5 times that of hot-dip galvanized sheet. Continuous or intermittent use at temperatures up to 490℃ will not cause serious oxidation or scale. The ability to reflect heat and light is twice that of hot-dip galvanized steel sheet, and the reflectivity is greater than 0.75, making it an ideal building material for saving energy.

Electrogalvanized substrate

The product obtained by using electrogalvanized sheet as substrate, coating with organic coating and baking is electrogalvanized color-coated sheet. Since the zinc layer of electrogalvanized sheet is thin, the zinc content is usually 20/20g/m2, so this product is not suitable for outdoor use in making walls, roofs, etc. However, due to its beautiful appearance and excellent processing performance, it can be mainly used in home appliances, audio, steel furniture, interior decoration, etc.

Color coated coil coating types

Polyester

Good adhesion, rich colors, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon-modified polyester

i.e. (SMP), good hardness, wear resistance and heat resistance of the coating, as well as good exterior durability and resistance to chalking, gloss retention, average flexibility, medium cost.

High-durability polyester

i.e. (HDP), excellent color retention and UV resistance, excellent outdoor durability and resistance to chalking, good film adhesion, rich colors, excellent cost performance.

Polyvinylidene fluoride

i.e. (PVDF), excellent color retention and UV resistance, excellent outdoor durability and resistance to chalking, excellent solvent resistance, good formability, dirt resistance, limited colors, high cost.